ABOUT US

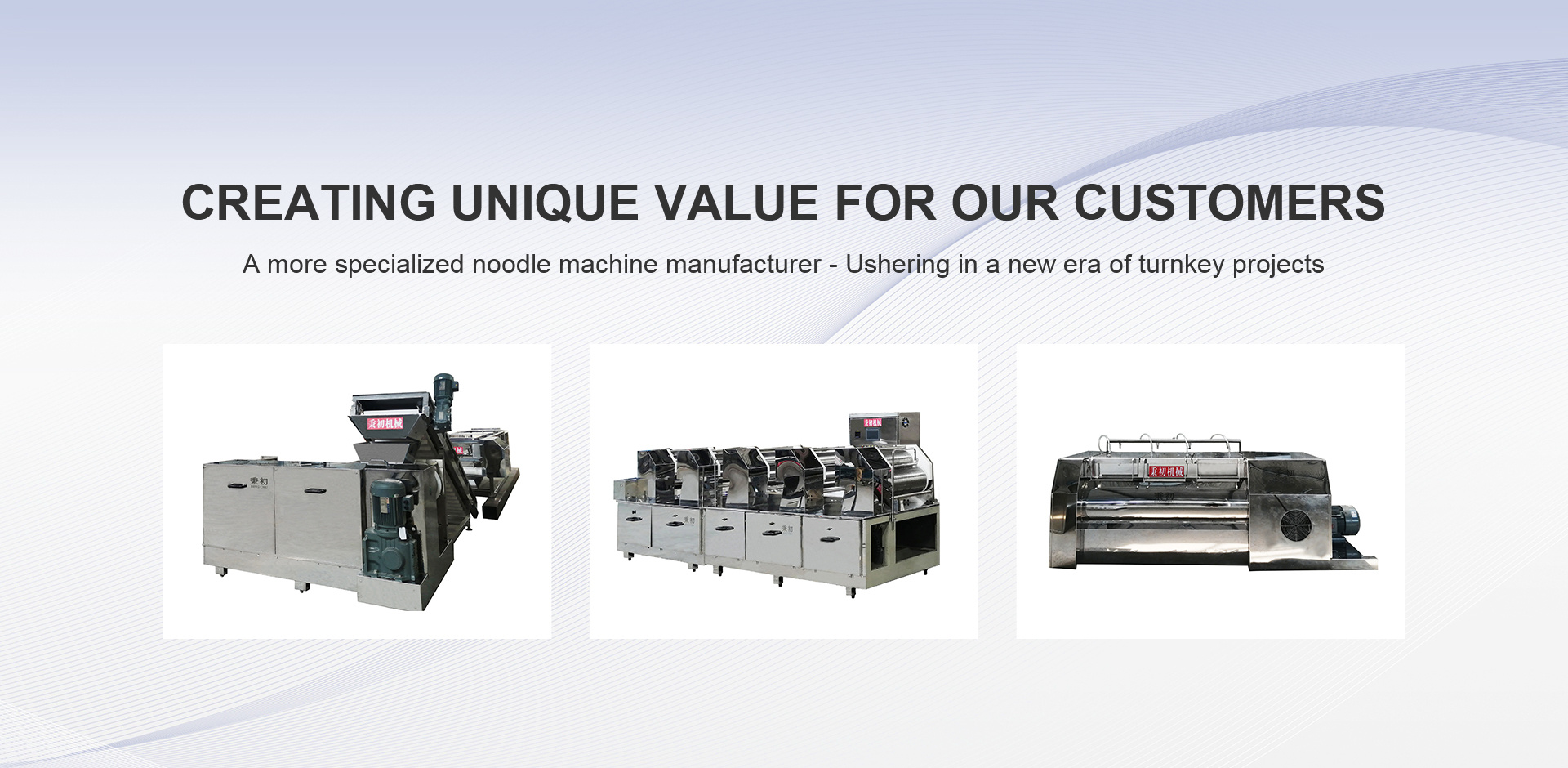

A more specialized noodle machine manufacturer - Ushering in a new era of turnkey projects

Zhengzhou Bingchu Food Machinery Co., Ltd. is located in China’s new first-tier city -- Zhengzhou city, which is an industry famous noodle machine equipment manufacturer for innovation and customization.

The company’s noodle machine equipment adhering to the concept and style of Japanese manufacturing: boutique positioning, precision manufacturing, fine installation, subvert the image of traditional Chinese noodle machine, mainly to meet and serve the innovative needs of global medium and high-end noodle products enterprises, and strive to create a new name card of Chinese noodle machine!

ADVANTAGE

Technical Advantages

Our R&D team, which has been working in the noodle machine industry for more than 20 years and has successfully designed and developed countless new types of equipment, is a group of knowledgeable elites who can be trusted and relied upon. They are not only the backbone of China's noodle machine innovation at present, but will also be the future leaders of China's noodle machines!

Product Advantages

1. Japanese style, novel and beautiful.

2. Energy saving and low consumption.

3. High degree of automation.

4. Mature and stable operation of the equipment.

Service Advantage

1. Real-time response to user problems, never delay.

2. 48 hours service in China (except for special cases).

3. 18 months of equipment warranty period.

4. 24 hours a day is the service time.

CASE

NEWS

In the past, fresh noodles were mainly rolled out by hand, but nowadays it has been commonly produced in workshops. The process flow of the fresh noodle production line is: water supply - flour supply - flour mixing - maturing - pressing, cutting - cooling -conveying - packaging - storage, etc. The semi-dry noodle production line is based on the raw noodle with the addition of high temperature drying and softening modeling process, and the moisture content of the finished product is generally between (20-25)%, and must also do antiseptic treatment. If you are interested in fresh noodles/semi-dry noodles production line, please contact us online or call us directly.13525548132。

The main process of producing boiled noodles is: water supply - supplying flour - mixing noodles - maturing - pressing, cutting - boiling noodles - loosening silk - cold noodles -Cutting - conveying - packaging - storage, etc. The main equipment corresponding to the process flow are: water supply system - powder supply system (or manual powder pouring) - noodle mixing machine - ripening machine - noodle pressing machine - noodle cooking machine - shredding machine -cold noodle machine - cutting machine - conveyor - packing machine, etc. If you are interested in boiled noodle/ hot dry noodle production line, please contact us online or call us directly.13525548132。

Non-frying is relative to frying, in fact, the production process is to replace the fryer with a non-frying dryer, the other equipment is basically the same, but the dryer is much larger and more complex than the fryer, so non-frying production line is more expensive than the same type of frying equipment. In recent years, the concept of non-frying has become popular, non-fried food is widely popular, if you are interested in non-fried instant noodle production line equipment, you can online consultation or direct telephone consultation what is the difference?13525548132。